Replication Potential of the Uhuru Park Pilot Project from Kenyan Perspective

The city of Nairobi in Kenya has a population of about 5 million people within the city itself, but the population is estimated to be about 10.8 million within the metropolitan area. The city is grappling with the issue of water, as the current production is about 500 000m3/day, against a demand of 800,000m3/day. Heavy infrastructure and capital are required to be able to bridge this Gap. A strategy that would help in reducing this gap would be most welcome. Sewerage coverage is estimated at about 50%, leaving about 50% to depend on on-site sanitation like septic tank and using exhausters and pit latrines in extreme cases. A method that would enable to bring up a decentralized wastewater treatment plant that do not require heavy infrastructure like sewer networks is most welcome.

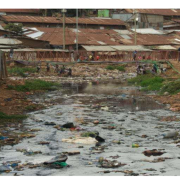

The city also has great challenges in the collection of wastewater and fecal sludge because of the fast-growing population due to rural-urban migration, which has accelerated the population growth. Rivers in the city are heavily polluted because of the overflow from the current sewer networks and the discharges from areas like focus settlement that are not connected. The open channel that was visible at Uhuru Park was initially meant to convey storm water but is currently used to conveying storm water melt with sewage from the overflow from diverse areas and institutions.

Currency in Nairobi, the most common wastewater treatment systems are stabilization ponds and aerated lagoon coupled with constructed wetlands as well as conventional treatment systems. But the main problem is that this requires huge infrastructure for collection of sewage and transporting it to a central point. So, the need for decentralized systems is key.

The photo on Page 4 (See attachment) is one of the rivers in Nairobi which is flowing next to an informal settlement; this picture presents the heavy pollution in the river and the environment. This has surely helped the Government to come up with the Nairobi River Rehabilitation Commission to try and clean up these rivers so that the water can be available for other uses. The system being discussed actually falls into that category of helping to clean the rivers. The initiative to have this decentralized system in Uhuru Park was initiated at a very high level, when the President of Estonia visited Kenya, and had discussions with her host President of Kenya on areas of bilateral cooperation. One of the results was that Estonia being fairly advanced in terms of technologies, especially in water and wastewater treatment, could assist Kenya in coming up with very innovative ways of treating wastewater, and that is how the Spacedrip device was booted. The Estonia President nominated the Spacedrip team which was accompanying her to do a pilot in Nairobi, and the Kenyan Government nominated the Nairobi Metropolitan services and the Executive Office of the President to work on the pilot. It was deemed appropriate to pilot this system in a very central place, where it can be accessed by other leaders and institutions from around the country. And that’s how the pilot was positioned in Uhuru Park (See Attachment, Photo in Page 7), one of the main recreation parks located within the Central Business District (CBD) in Nairobi. Anybody coming for recreation within the park can see it. The map (See attachment, Page 6) presents in light green the Uhuru Park, which is a very centrally placed within Nairobi CBD with the major governmental institutions located in close proximity including even the Parliament, the President’s Office, the city hall, major hotels and other business premises.

Uhuru Park was chosen for this pilot because before the installation of this system, potable water was used to irrigate the Park, which is a huge area of over 50ha, with the corresponding pressure on potable water. Indeed, the city is already experiencing a deficit of 300 000, and instead of saving on the water, the same water is used for irrigating the park. So, the idea of putting this system in the Uhuru Park was to make sure that the effluent treated from the system would be used to irrigate the park, and by so doing help in reducing the pressure on demand on the drinking water.

Aqua Consult Baltic designed the technology enabling to connect with the irrigation infrastructure of the Uhuru Park, and there has been a partnership on the consultation during the commissioning and six-months operation of the plant handed over to Nairobi Water Sewage Corporation (NSWC). Ruji Africa was the local partner of Spacedrip helping in the preparation, installation and piloting the automated wastewater treatment and reuse system. We have already obtained an update on environmental impact assessment from a Regulator, which is the National Environment Management Authority.

One of the key benefits of this water reuse system is that it requires a very small space, and the container system can be installed inside a building or smaller areas, unlike the other systems which require huge plots of land (land in a city like Nairobi is very scarce to get). This is therefore a solution to areas that do not have land. The efficiency of the system lies in the total pathogenic removal for key area, because the effluent can then be used for other uses like irrigation. In the future, effluents from this system could also be used in flushing of toilets and cleaning as the case maybe, since most of the water is used for cleaning services. For now, because of the stigma associated with the sewage water, it might be too early to start talking about using it for drinking. It already helps to reduce pressure on drinking water, and it is estimated that adopting this water reuse technology in most of the heavy consumers of water (like tourism, hospitality industries, informal settlements, commercial and residential buildings, food processing…) could help cut the demand for water by about 50%, and then the pressure on potable water could really come down.

One key input of this system is electricity because of both the automation and the pumping within the system. However, this can be addressed in future. Currently, the system also incorporates a partner’s solar system that produces part of the electricity, especially for automation and critical operations of the system. But in future, we think the solar energy should be made the main source of energy by incorporating more solar panels and batteries to store the energy.

Financially, this system gives an advantage, especially saving on heavy cost for the construction of the infrastructure required for centralizing the system. This is the main cost that applies for the sewerage system. With a decentralized technology and no need for heavy infrastructure, specific saving in the cost makes this system a big advantage.

The result of this piloting is supposed to inform and advise the policy makers and help them in the development of by-laws that would be required for some institutions. With the water consumption and discharge of given capacity, it should be of interest to install this water treatment and reuse system in the tourism and the hospitality industry, urban, commercial, building institutions, and the food processing industries. Doing so will also help the private sector participation accelerating the coverage in terms of sewerage and help those involved in the management and control of water demands. So, as an addition to constructing new infrastructure to bring in more water, we can manage the quantity we have better by treating our effluent and reusing it. This is already happening in buildings like the local university of Nairobi, which is harvesting all the water within the building that is then reused in flushing of toilets. This idea is not very far-fetched, and its time has come. Policy-makers need to be advised on that so as to come up with necessary bylaws to help manage the water demand distribution in the country.